MEMS Optical Cross Connect Switch (OXC)

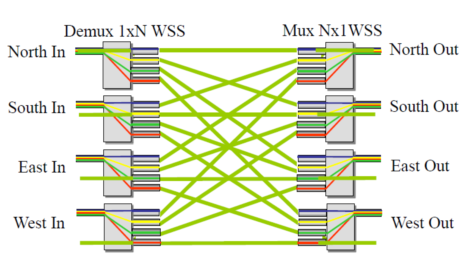

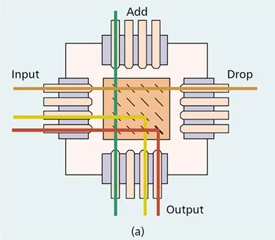

Optical cross-connect switch (OXC) is a matrix optical switch with NxN ports. It can be used to build a CDC ROADM system (colorless, directionless, contentionless reconfigurable optical add/drop multiplexer).

OXC can be built with a 1xN port optical switch. In order to build NxN port OXC module, it needs 2N 1xN port optical switches. The size and cost of the OXC module increase dramatically when the number of port increases, so the port number of this OXC is usually limited to 32x32 ports.

4x4 OXC module built with 8 1x4 switches

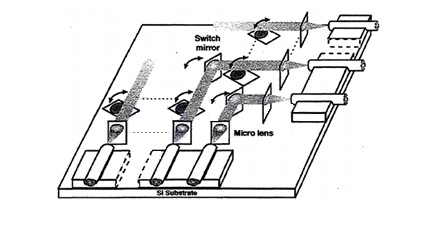

2D MEMS optical switch

The second technical solution to realize OXC is a Cross-Bar optical switch based on a MEMS mirror array. It has 2 input ports and 2 output ports. The optical path switching is achieved through 4 MEMS mirrors. Every mirror has two states, lying horizontally on the substrate to allow the beam to pass through (OFF) or standing upright on the substrate to reflect the beam (ON).

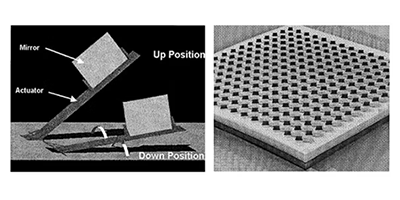

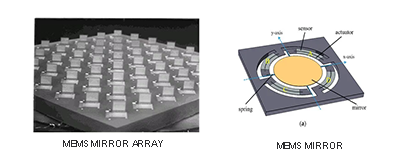

SEM photos of the MEMS chip and a single mirror, as well as MEMS torsion mirror. The mirror is supported by a polysilicon beam. When there is no voltage applied to the electrode, the mirror remains horizontally. When powered on, the mirror stands upright on the substrate driven by electrostatic force.

Matrix optical switches based on 2D MEMS technology require a NxN scale mirror array to make a NxN optical switch. All optical paths of the device are in one plane, that is why it is called a 2D MEMS optical switch.

First Generation 2D MEMS matrix switch

The switching of the optical path is achieved through a mirror. The mirror is hinged on the base. One end of the two pull rods is connected to the mirror, and the other end is connected to a translation stage. The translation stage is driven by a scraper-type actuator to pull the mirror forward. The mirrors rotates as they are pulled.

2D MEMS Mirror Array

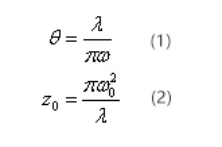

Matrix optical switches based on 2D MEMS mirror arrays have the advantages of simple structure and easy packaging, but their scalability is limited. For different port link relationships, the optical path lengths vary greatly, which will introduce coupling losses and loss uniformity. The tolerance for the optical path difference depends on the beam size in the free-space optical structure. According to equation (1), the smaller the spot ω0 is, the more divergent it is. According to equation (2), the shorter the collimation distance is.

The coupling situation between two single-mode fiber SMFs increases sharply as the spacing between the fiber end faces increases. The spacing between two single-mode fibers is usually limited to <20μm. To increase fiber spacing to allow the placement of various free space optical components, thermal expanded core (TEC) fibers or lens fibers are usually used. Both TEC fiber and lens fiber can expand the spot size to be suitable for free space light transmission. The distance between two TEC fibers can be up to 10mm, while the distance between two lens fibers can be up to 50mm. For applications that require longer free space optical paths, collimating lenses are often required.

Applying TEC fiber or lens fiber to 2D MEMS optical switches helps to increase the free space optical path length to accommodate more MEMS mirrors and expand the optical switch port. However, the maximum allowed spot size is limited by the size of the mirror, which depends on the MEMS design and process. Mirror diameterФ>3ω0 is usually required to reflect more than 99% of the optical power. Therefore, the maximum port number of 2D MEMS optical switches is usually limited to 32×32.

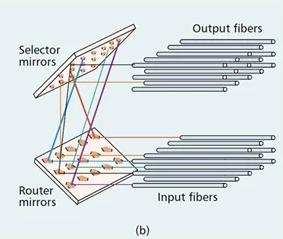

OXC based on 3D MEMS technology

In order to further develop OXC system, 3D MEMS optical switches were developed. The basic structure of 3D MEMS OXC includes two MEMS mirror arrays and two two-dimensional fiber collimator arrays. Each input fiber collimator corresponds to a mirror in the first MEMS chip, and each output fiber collimator The straightener corresponds to a mirror in the second MEMS chip. All mirrors on the MEMS chip can deflect in two axes.

The beam from each input port is independently controlled by a mirror on the first MEMS chip and directed through biaxial deflection to another mirror on the second MEMS chip (corresponds to the output port). A mirror adjusts the direction of the reflected beam to point to the output through biaxial deflection. Therefore, through the control of two MEMS chips, optical signals can be exchanged from any input port to any output.

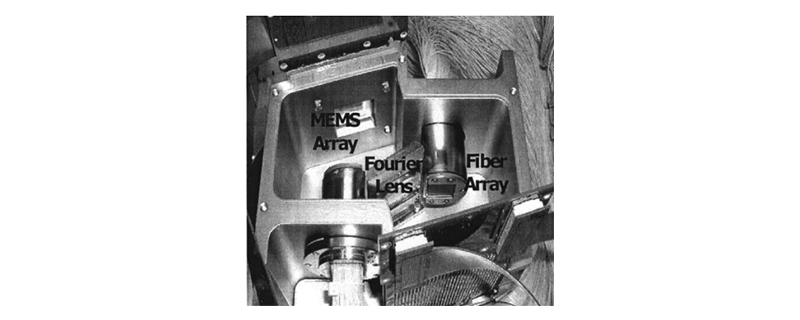

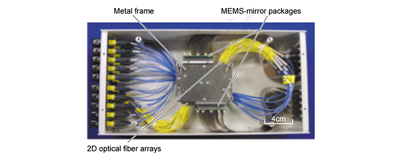

The OXC developed by Bell Labs includes two MEMS mirror arrays, two 2D fiber arrays and a Fourier lens. Each input-output link is built through a mirror on the first MEMS chip and another mirror in the second MEMS chip.

The new generation 3D MEMS OXC from NTT Lab replaces Fourier lenses with a circular concave reflector. The use of a circular concave mirror can reduce the off axis aberration of the edge port to reduce insertion loss.